Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

WTTEC has partnered themselves with the largest steel and concrete building manufacturer in the world. The unique and patented approach to construction has changed the landscape for generations to come.

Cellate fully owns and promotes the patents and copyrights of the unique Cellate Extended End Fibre Steel and the Cellate Precast system, which is widely regarded as the most advanced prefabricated building system in the world and has been used in the construction of thousands of different structures spanning the globe.

Cellate unique technology which has successfully evolved since 1964 by a core team of professionals.

The “CELLATE™” Fibre Steel Concrete is a patented proprietary

product and a great advance in construction industry. This

technology has the capacity to innovate and instigate change in

the current labour intensive construction industry.

Cellate & WTTEC is a “one stop shop” for Project Development and construction. Possessing the technology, the experience and the history in producing built structures in a prefabricated nature, using the unique and patented Cellate Fibre Steel and Precast Concrete System, We are able to deliver projects faster, more affordable and of higher quality whilst improving the workplace health and safety and reducing the carbon footprint and waste generation on the environment from the development itself.

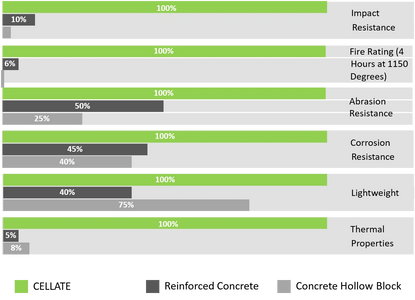

• Concrete with twice the abrasion resistance of ordinary

concrete.

• Over twice the punching sheer resistance of ordinary concrete.

• Higher fatigue resistance permitting more repetitions of loading

without distress.

• Four times the impact resistance of ordinary reinforced

concrete.

• Young’s modulus and Poisson's ratio are unaffected by the Fibre

Steel introduction.

• Corrosion resistance is high - Twenty years exposure to the

seawater has shown that negligible corrosion takes place

beneath the surface of concrete; no evidence has been shown

that Cellate™ Fibresteel Reinforced Concrete can cause a

Spalding (concrete cancer).

• Maximum Deflection Ratio: Cellate has a span to depth ratio of

50:1 allowing for a reduction in the number of beams and

columns.

The “CELLATE™” Fibre Steel Concrete is a patented proprietary

product and a great advance in construction industry. This

technology has the capacity to innovate and instigate change in

the current labour intensive construction industry.

With the development of EE Fibersteel fibers, Cellate was able to develop a patent innovative precast system using thin walled products. This product enabled Cellate to construct and deliver turn-key affordable housing, high rise towers and large villa developments around the globe. Cellate has constructed numerous projects spanning the globe, ranging from smaller residential developments in Sri Lanka and the Caribbean to large mass housing in United Arab Emirates, to tall towers in Sydney, Australia. The use of the Cellate Fibre Concrete Precast system has allowed faster construction with lower costs and minimal construction waste.

The innovative design of the panels allows larger panels to be installed at greater spans with reduce jointing. The panels are significantly lighter than conventional precast and insitu concrete thus allowing shallower and lighter foundations of the buildings.

The panels are uniquely designed with high thermal and fire resistance levels making the system highly suitable to residential buildings, reducing the overall running costs of each dwelling, and reducing the carbon footprint on the environment.

Cellate Fibre Steel Precast Technology has unique properties that make the system tailor made for commercial and retail projects. Enabling large column free spans with thin slab profiles, producing a product that is tailor made for the designs of offices and shopping centers. The lightweight nature of the panels allows the panels to be cast in large formats whilst not having a significant impact on crane costs.

Sports and Leisure buildings are unique in their nature and usually contain significant structural members to achieve the iconic designs of each venue. Cellate using the high strength properties of the Cellate EE Steel Fibre and the use of prestressed Cellate Precast elements have been able to achieve designs in concrete members usually left for steel structures. Cellate has delivered the iconic Dubai Creek Gold Club, completing the worlds first long span column-free concrete roof to this iconic building. The use of conventional concrete would not have been able to achieve such a design.

Cellate, using fibre steel and precast, was able to deliver a unique and iconic precast grandstand and 30m precast cantilever roof in the UAE. Cellate possesses a unique technology and construction process that can use concrete in ways that would normally not be considered. This flexibility and strength properties allows Cellate to deliver any iconic sporting or leisure development around the globe.

The structural strength and density of Cellate Fibre Concrete and Precast makes it an ideal choice for safe rooms, bunkers, blast structures, vehicle barriers and many forms of permanent or temporary protection. Cellate Fibre Concrete and Precast has 6 times greater impact resistance than normal concrete making it ideal for these purposes. Cellate can easily be installed for protection in tornado-prone and hurricane-prone areas, and in areas of High Seismic Activity.

Cellate concrete can resist massive impacts, so it makes an ideal material for security around public structures. Whether in day-to-day use as a median barrier or for protecting the perimeter of a building, precast structures can be designed to absorb the impact from vehicles, redirect them and/or slow them down. In extreme applications, blast protection from explosions may be a necessary design specification. Precast concrete components perform a critical role in defense

Since 1995, The WTC twin towers in Colombo have withstood TWO separate terrorist bombings with no structural damage. With the unique anti-ballistic characteristics of the Cellate Fibre Steel Precast we have successfully completed a significant number of confidential defense projects throughout the Middle East on behalf of The MOD – UAE, Ministry of Defense UK, USA, KSA

Since 1995, the WTC twin towers in Colombo have withstood TWO separate terrorist bombings with no structural damage.

Cellate process and storage tanks built for highly corrosive salt slurry in UAE are still defect free after 20 years.

Cellate sea retaining wall in Sydney Australia has suffered negligible corrosion after 30 years of tidal waters.

Many lives have been saved using Cellate for Anti-Ballistic applications world wide.

We have successfully completed a number of confidential defense projects throughout the Middle East and on behalf of Ministry of Defense UK, USA and KSA

Left Half - 20T payload slammed into a Cellate panel wall at 100 Kph during impact testing.

Top Right – Anti-ballistic Properties of T2 Cellate Fibre Reinforced Panels being subjected to rapid fire.

Bottom Right– Concrete Test pieces subjected to heavy gun fire with and without SFRC.

In civil engineering applications, high-strength concrete is often desirable, and precast components can be cast to meet such demands. If high early strengths are needed, this can be achieved through high-performance concrete, custom mix designs or accelerated curing methods at the plant. Where point loads or high bearing stresses are likely, the dense, high-quality reinforced concrete in a precast concrete structure is absolutely critical.

Steel Fibres have been successfully used for pavement applications in many hundreds of thousands of square meters of concrete. It has been used as the primary reinforcement for commercial and industrial pavement projects such as, heavy duty workshop floors, heavy duty tiles, roads, roundabouts, airport runways, bridges, jetty overlays, boat and barge ramps, hardstand areas, bike paths, factory and warehouse floors.

The use of Steel Fibres reduces labor and material costs because it allows rapid site preparation and speedier concrete placement with the elimination of conventional reinforcing. All of these features combine to make Cellate Fibre Concrete more economical both during construction and over the life of the infrastructure project

Cellate concrete is corrosion resistant and can be used with confidence in very aggressive environments. For example, Fibre concrete piers and pontoons are resistant to microbial attack experienced in marine environments. Tight quality control in production means that Cellate Fibre Steel Concrete and Precast is ideal for structures within a marine environment. Cellate Fibre Concrete will not support the classic galvanic corrosion cells which cause corrosion in conventional reinforced concrete. The fibres being discreet and non-continuous provide no mechanism for propagation of corrosion.

Cellate concrete and precast is ideal for use in:

Pontoons

Jetties

Moorings

Marine Piles

Boat Ramps and Slips

Underwater Structures

Flood Mitigation

Sea Level protection

Sea Walls and Revetments

WTTEC

CANADA

Copyright © 2020 WTTEC - All Rights Reserved.

info@wttec.ca

This website uses cookies. By continuing to use this site, you accept our use of cookies.